Researchers at Zhejiang University in east China's Hangzhou City have made a groundbreaking advancement in 3D printing technology by developing elastomers with exceptional strength and toughness. Published in the prestigious journal Nature, this breakthrough addresses longstanding material limitations in 3D printing, paving the way for large-scale production of high-performance products.

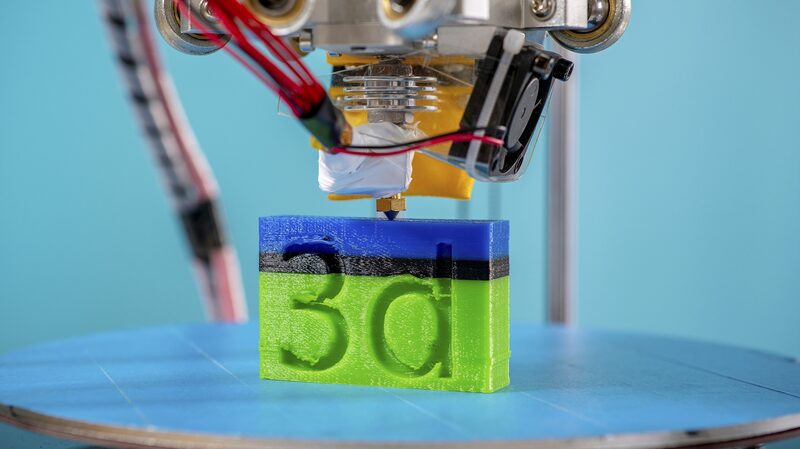

3D printing, renowned for its ability to create geometrically complex and customizable products, has faced challenges in mass manufacturing due to low print speeds and inadequate mechanical properties. Although recent advancements in ultra-fast 3D printing of photo-polymers have boosted manufacturing efficiency, the mechanical performance of these polymers still lags behind traditional processing techniques.

Speaking on the significance of the research, Professor Wu Jingjun stated, \"This innovation brings new hope for the widespread application of 3D printing in various industries.\"

The team, led by researcher Fang Zizheng, developed a novel 3D photo-printable resin chemistry that results in an elastomer boasting a tensile strength of 94.6 MPa and toughness of 310.4 MJ/m³—both surpassing any existing 3D-printed elastomers. Demonstrating the material's resilience, the researchers printed a rubber band that could stretch up to nine times its original length and withstand a tensile strength of 94 MPa without breaking. Additionally, the material was used to create objects like puncture-resistant balloons, showcasing its versatile applications.

This advancement not only enhances the durability and functionality of 3D-printed products but also opens doors for innovative designs and applications across multiple sectors, solidifying 3D printing's role in the future of manufacturing.

Reference(s):

Researchers develop 3D printable elastomers with exceptional strength

cgtn.com