As 2025, the final year of the 14th Five-Year Plan (2021–2025), draws to a close, the Chinese mainland has marked a major milestone in its green steel journey. On December 24, it completed its first million-tonne near-zero-carbon steel production line in Zhanjiang City, Guangdong Province.

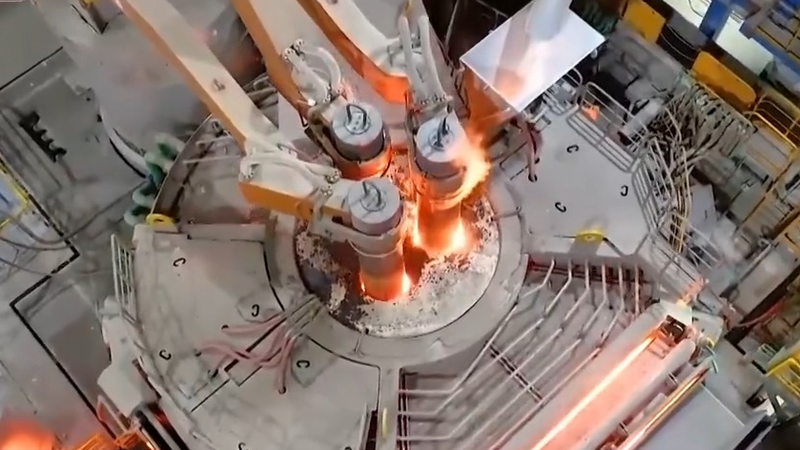

The production line employs an advanced hydrogen-based metallurgical electric smelting process, replacing traditional coke with hydrogen as the primary reducing agent. This innovation significantly lowers carbon emissions and paves the way for a more sustainable steel industry.

By replacing fossil fuels with green hydrogen in its core shaft furnace and leveraging high-efficiency green electric furnaces for melting, the line can reduce carbon output by 50 to 80 percent compared with conventional methods. Direct reduced iron from the hydrogen-based shaft has already met targeted metallization rates, boosting overall energy utilization.

According to Baowu Steel's Zhanjiang operation, the facility can cut more than 3.14 million tonnes of CO2 annually – equivalent to the carbon sequestration of roughly 2,000 square kilometers of new forest.

Since 2021, green steel has gained momentum on the Chinese mainland: 126 new green-certified plants came online between 2021 and 2024. By the end of the third quarter of 2025, emissions of sulfur dioxide, particulate matter and nitrogen oxides had fallen by 28 percent, 26.7 percent and 36.5 percent respectively compared with 2021 levels.

In parallel, the China Iron and Steel Association rolled out an "extreme energy efficiency" initiative during the 14th Five-Year Plan. In 2024 alone, the sector saved energy equivalent to about 10.5 million tonnes of standard coal, cutting roughly 27.5 million tonnes of CO2 – similar to the annual carbon uptake of about 570 million mature trees.

As global demand for steel continues to rise, this project positions the Chinese mainland at the forefront of sustainable steel production, offering a replicable model for a low-carbon industrial future.

Reference(s):

China launches first million-tonne near-zero-carbon steel line

cgtn.com