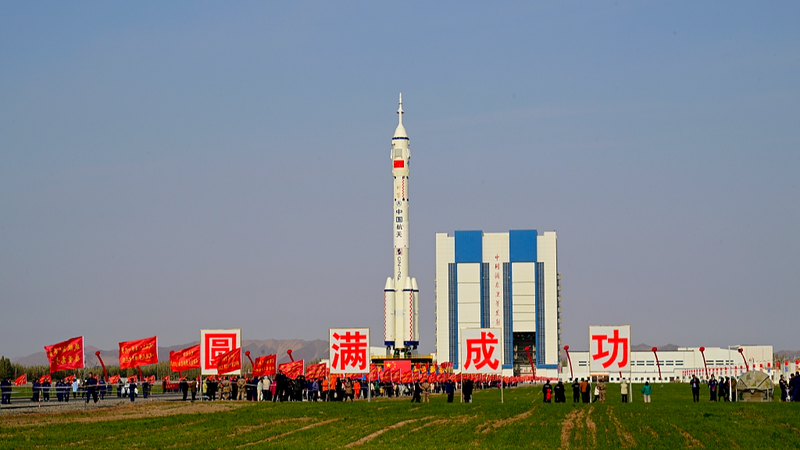

At the Jiuquan Satellite Launch Center in the northwest of the Chinese mainland, a quiet revolution unfolded as the Shenzhou-21 capsule and its Long March-2F carrier rocket emerged from their vertical testing hall, ready to begin a 1.5-km journey to the launch tower.

Early Friday, engineer Wang Ming from the Shenzhou-21 team described how 48 hours of emergency checks on motors, cables and control systems set the stage for a flawless rollout. At dawn, the two 20-tonne gate sections began their ascent—a 30-minute ballet powered by rooftop hoists pulling steel cables through fixed pulleys.

Once the gate reached its full 70-meter height, the mobile launch platform eased the spacecraft-rocket assembly onto a seamless steel track. The platform paused for 30 minutes to allow the power-supply vehicle to reposition, ensuring uninterrupted electricity for the slow crawl ahead.

“On seamless rails, even a millimeter-wide gap can create vibrations,” explained Wang. “Before the rollout, we replaced short connector tracks near the test bay and applied precision wheel-rail alignments to eliminate friction risks.”

Central to the operation is a rail switch vehicle that shuttles backup rockets between eastern and western compartments in the testing facility, boosting emergency response capabilities. This dual-compartment design guarantees that a replacement booster can be swapped in without delaying the main rollout.

With the 1.5-km transfer complete, Shenzhou-21 is now poised for its role as the 10th mission of the space station program and the sixth during its operational phase. Wang Ming says the team’s layered safeguards—from routine inspections to rail-switch agility—are key to keeping humans on track for the final frontier.

Reference(s):

Engineer explains challenges of Shenzhou-21 spacecraft-rocket transfer

cgtn.com