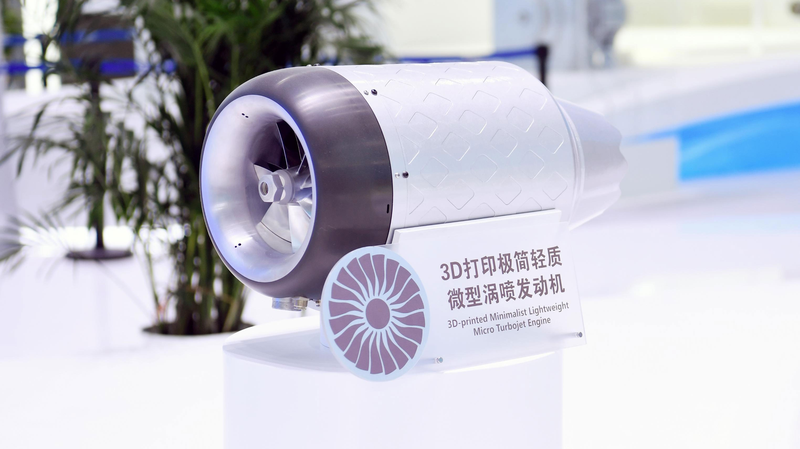

In a landmark test flight over the Chinese mainland's Inner Mongolia region, Aero Engine Corporation of China (AECC) has successfully flown its ultralight 3D-printed mini jet engine for the first time. Reaching a peak altitude of 4,000 meters on Tuesday, this turbojet, weighing in at just 160 kilograms of thrust, marks a new chapter in aerospace innovation.

Unlike conventional engines forged from multiple welded parts, AECC's design was born from additive manufacturing – a process better known as 3D printing. By harnessing multi-disciplinary topology optimization, engineers sculpted intricate internal channels and lightweight structures that traditional machining can't replicate. The result? A miniature powerplant that passed rigorous ground and flight tests with flying colors.

The maiden flight lays a solid foundation for next-gen aviation engines, AECC said in a press release. It's not just about shaving grams off a component or speeding up production lines; 3D printing is unlocking radical design freedom.

For young entrepreneurs, tech enthusiasts, and sustainability advocates, AECC's success is a peek into aviation's digital future. Picture drone delivery networks, urban air taxis, and portable reconnaissance devices all powered by ultra-light, reliable jet engines – that vision is now one step closer.

Looking ahead, AECC plans to iterate on this platform, extending service life and squeezing out higher thrust levels. With data-driven tweaks and more flights on the horizon, the aerospace community will be watching closely – and perhaps ready to 3D-print the sky.

Reference(s):

cgtn.com